TOLL Shipping has 2 new builds each with 2 slow speed HYUNDAI MAN B&W 9S40ME-B9.5-TII main engines

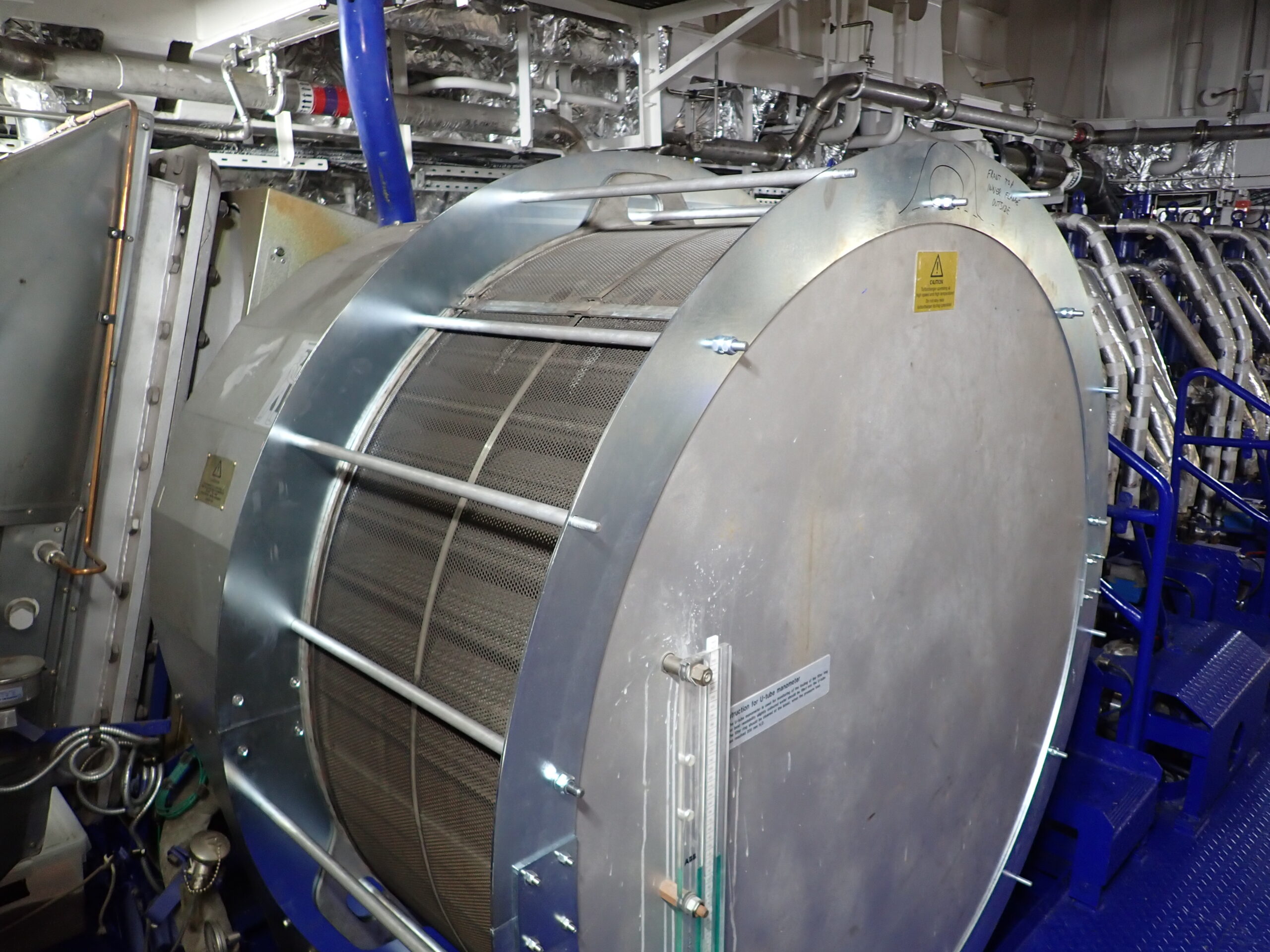

Each main engine has an ABB A170L37 turbocharger with a fabricated steel Air Filter Silencer with a diameter of 1280mm x inlet area of 520mm.

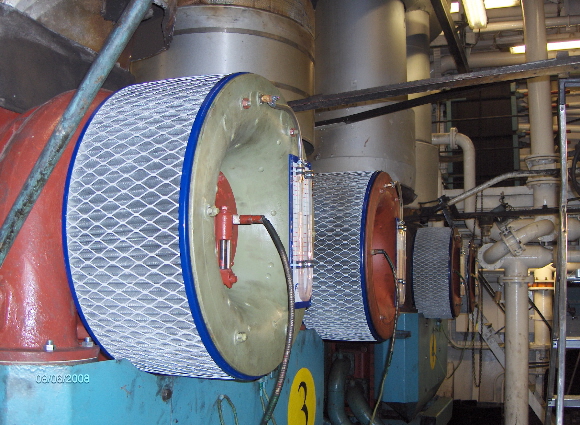

The standard air mat is used over the top of a metal mesh and a fine nylon screen. The company wanted to reduce waste as well as maintain the efficiency of the engines, which is important on a time critical service.

A framework of steel flanges and spacer bars is used to hold and support a PMAX Filter in place on the AFS. No modifications to the OEM, AFS was necessary to fit the PMAX Filters.

Manufactured in 2 pieces, the PMAX Filter fits very easily on to the carriage assembly.

Running with the standard OEM filter plus wrap the DP was over 200mm water gauge, (WG). The PMAX filter reduced to differential pressure to 140mm water gauge. The OEM manometer seen here at normal full away load is reading 140mm WG whilst the PMAX manometer is reading 80mm WG. The reason for the difference in the 2 manometers is due to where the sensing points on the AFS’s are. Water gauge is a very sensitive and light medium to measure air differential pressure.

The OEM filter is a simple wrap, measuring 4M in length while the length of the PMAX filter with it’s pleated form is 12.6M. The extra material is not only important for air flow but also allows a greater dirt load to be carried within the element, without reducing air flow. The PMAX filters are washed once a month and have now been in constant use for over 2 years with absolutely no issues at all.